COMPREHENSIVE DESIGN, ANALYSIS AND CERTIFICATION FROM CONCEPT TO COMPLETION IN FIVE MONTHS OR LESS, IN MOST CASES

With more than 40 years of Part 121 experience, we have become FAA regulatory experts and a reputable partner with virtually all divisions, including Aircraft Certification Office (ACO), Aircraft Evaluation Directorate AED), and Manufacturing Inspection District Office (MIDO). Consortia Aerospace Group offers full Designated Engineering Representatives (DER) and Designated Airworthiness Representatives (DAR) services covering every discipline (except propulsion) and certifications capabilities equivalent to an ODA. Our DAR manufacturing capabilities include airworthiness, experimental, Radio Equipment Directive (RED) conformity certifications and 1st articles.

Full design, analysis and certification services with staff of DERs/DARs with FAA delegations in all systems, all structures (excluding Propulsion)

ENGINEERING SERVICES:

DESIGN

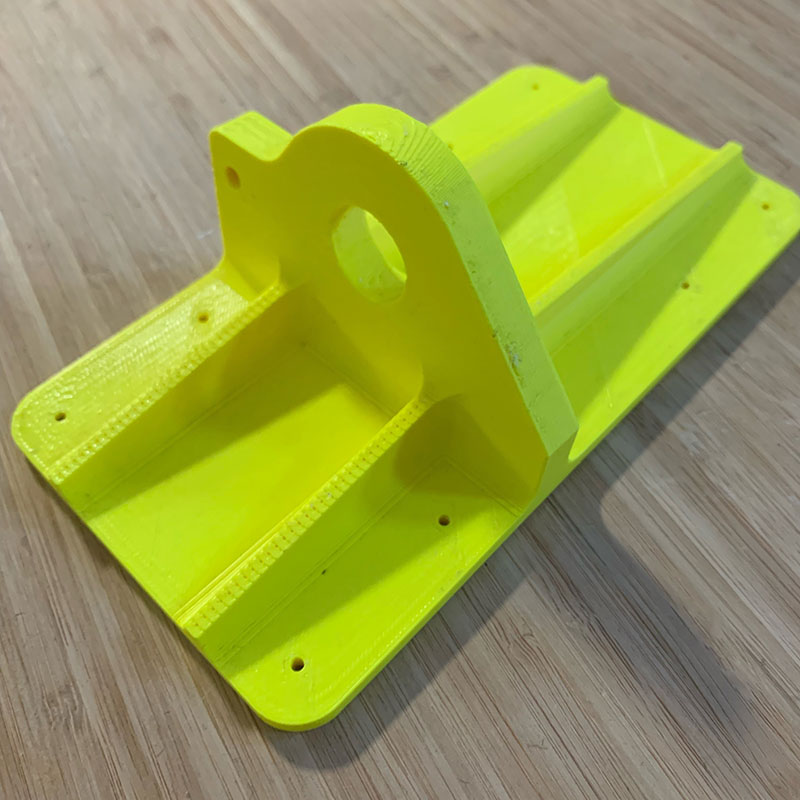

- New product development and existing design refinement

- Develop 2D and 3D engineering drawings of articles and assemblies using AutoCAD and Solid Works

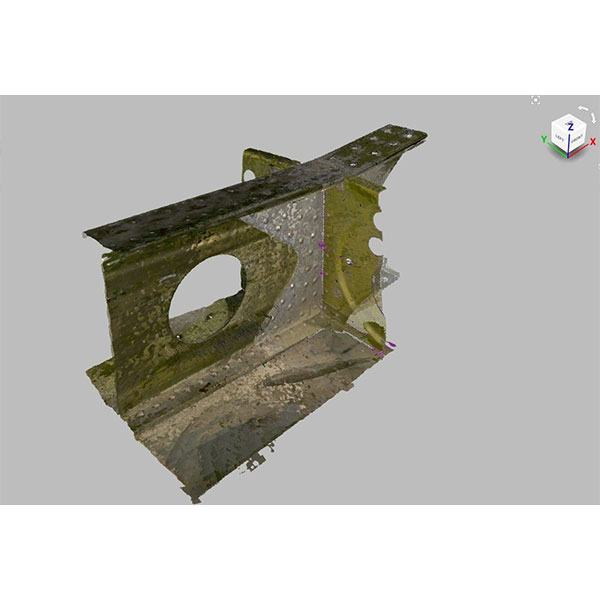

- 3D scanning using laser, blue light technology, white light, color, texture and geometry mapping

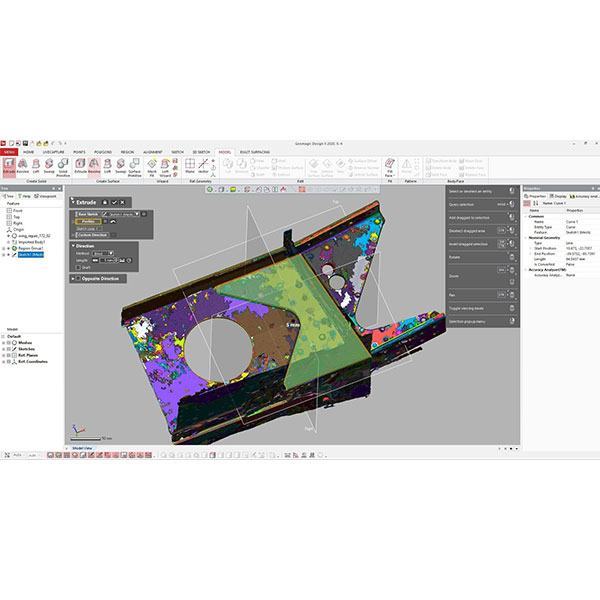

- Ability to convert 3D scan data into a solid model using Geomagic Design X

DAMAGE TOLERANCE ANALYSIS

- Consortia Aerospace in-house DERs can perform and approve damage tolerance analysis for a wide variety of aircraft. Using our proprietary load spectrum data, Consortia Aerospace provides better inspection intervals that more accurately reflect the actual flight profiles of in-service aircraft.

- Classical stress analysis of structure comprised of plates, beams, rods, etc.

- Complex or built-up structure analysis

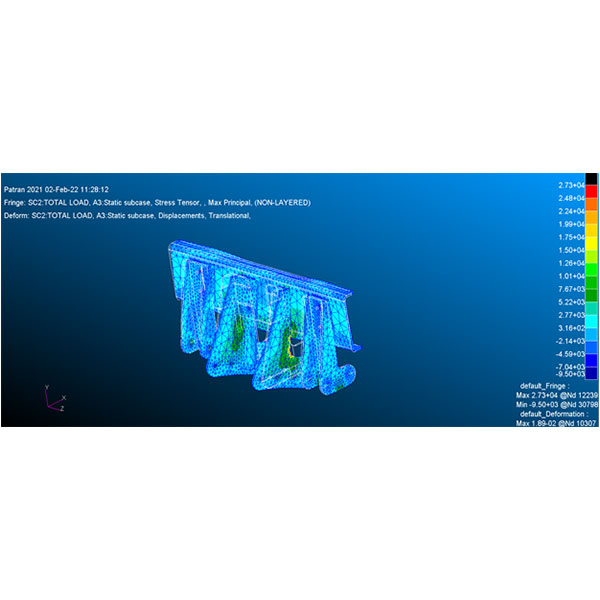

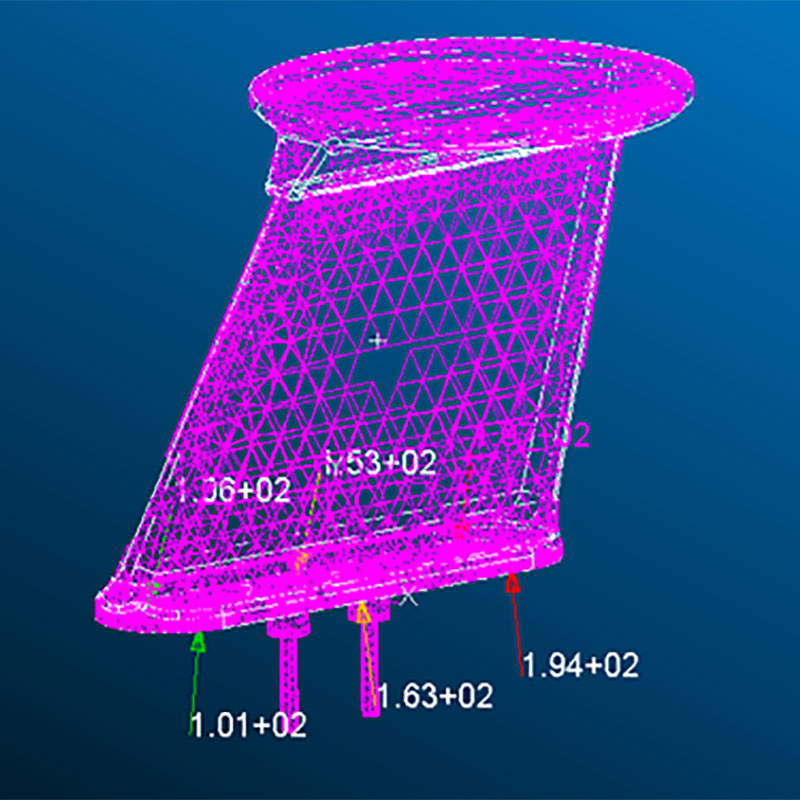

- Finite element modelling with Nastran/Patran

CERTIFICATIONS:

AVIONIC UPGRADES AND MODIFICATIONS

From full glass cockpits to hardware upgrades, we’ve certified a multitude of products across hundreds of platforms. Check our STC page for a full listing of our supported certifications.

INTERIOR AND STRUCTURAL CHANGES / CERTIFICATIONS

Interior reconfigurations, LOPA modifications, antenna relocations and other structural mods often present challenges for operators. With an entire engineering staff with structural delegations and experience, we are your one-stop shop for aircraft structural changes.

OTHER COMPLEX CERTIFICATION PROGRAMS

When clients ask for solutions to complex problems, we answer the call. We pride ourselves on out-of-the-box problem solving, always in compliance with regulatory requirements. We’ve design ferry fuel systems for the ERJ and CRJ series aircraft as well as the first domestic Airborne Bio-Containment System in the Gulfstream III, used to transport Ebola patients.

Got a complex engineering problem? Ask us if we can help.